Jun 14,2023

Metal brackets are versatile hardware components widely used in various industries for their strength, durability, and reliability. From construction and carpentry to furniture assembly and automotive applications, metal brackets are crucial in providing structural support, reinforcing connections, and ensuring stability. In this article, we will delve into the world of metal brackets, exploring their different types, applications, and significance in various fields.

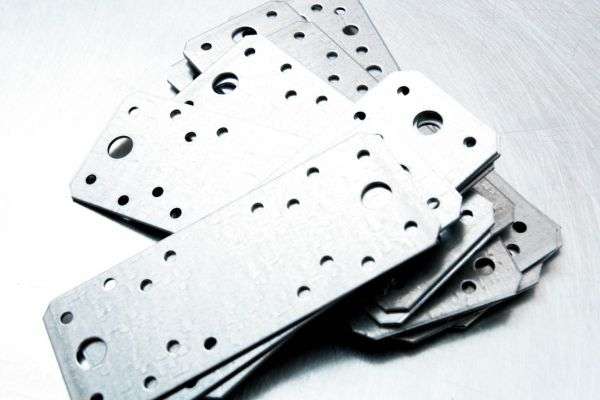

Metal brackets are hardware components made from various metals, including steel, aluminum, and iron. They are designed to provide structural support, enhance stability, and facilitate secure connections in multiple applications. These brackets come in various shapes, sizes, and configurations, each serving a specific purpose based on the project's requirements or industry.

Metal brackets come in diverse types, each tailored to meet specific needs and applications. Here are some commonly used types of metal brackets:

These brackets have a right-angle shape resembling the letter "L." They commonly provide corner support, reinforce joints, and secure two surfaces together.

As the name suggests, these brackets have a T-like shape. They are often used to join two components at a right angle, providing stability and support.

U-shaped brackets, also known as U brackets or strap brackets, feature a curved shape resembling the letter "U." They are widely used for securing pipes, cables, and other round objects to surfaces.

Angle brackets are designed with two perpendicular arms, forming an L-shape. They are commonly used for reinforcing corners, joining beams, or supporting shelves.

These brackets are specifically designed for supporting shelves. They come in various styles, such as floating shelf brackets, decorative brackets, and adjustable brackets, providing functionality and aesthetic appeal.

Metal brackets find applications across various industries and sectors due to their versatility and reliability. Here are some key areas where metal brackets are extensively used:

Metal brackets are integral components in construction and architecture. They provide essential support, stability, and reinforcement in structural frameworks, such as buildings, bridges, and towers. Metal brackets are used for connecting beams, trusses, and columns, ensuring the structural integrity of the entire construction.

In furniture manufacturing and assembly, metal brackets are crucial in joining different components. They provide strength and stability to furniture pieces like tables, chairs, cabinets, and bed frames. Metal brackets ensure durable connections and contribute to the overall longevity and functionality of the furniture.

Metal brackets are widely used in the automotive industry for various applications. They support and reinforce vehicle components, such as chassis, suspension, and exhaust systems. Metal brackets in the automotive industry are designed to withstand high loads, vibrations, and harsh operating conditions.

Metal brackets are essential in electrical and plumbing installations. They provide secure mounting for electrical boxes, conduits, and piping systems. Metal brackets ensure proper alignment, stability, and safety in these critical systems, preventing damage and ensuring efficient operation.

Metal brackets are versatile components used in various industries for strength, stability, and reliable connections. Metal brackets provide crucial support and reinforcement from construction and furniture assembly to automotive applications and electrical installations. Understanding the different types of metal brackets and their applications helps select the right bracket for specific projects, ensuring structural integrity and longevity. So, next time you come across a sturdy piece of furniture or a robust building frame, remember the significance of metal brackets in creating strong and secure connections.

Here are some frequently asked questions about metal brackets:

A: Yes, many metal brackets are designed for outdoor use. However, it's vital to choose brackets made from materials resistant to corrosion, such as stainless steel or galvanized steel, to ensure their durability in outdoor environments.

A: Yes, some manufacturers offer customization options for metal brackets. Customization may include variations in size, shape, hole patterns, and finishes to meet specific project requirements.

A: Yes, each type of metal bracket has its load-bearing capacity. It is essential to refer to the manufacturer's guidelines and specifications to ensure proper usage and prevent overloading.